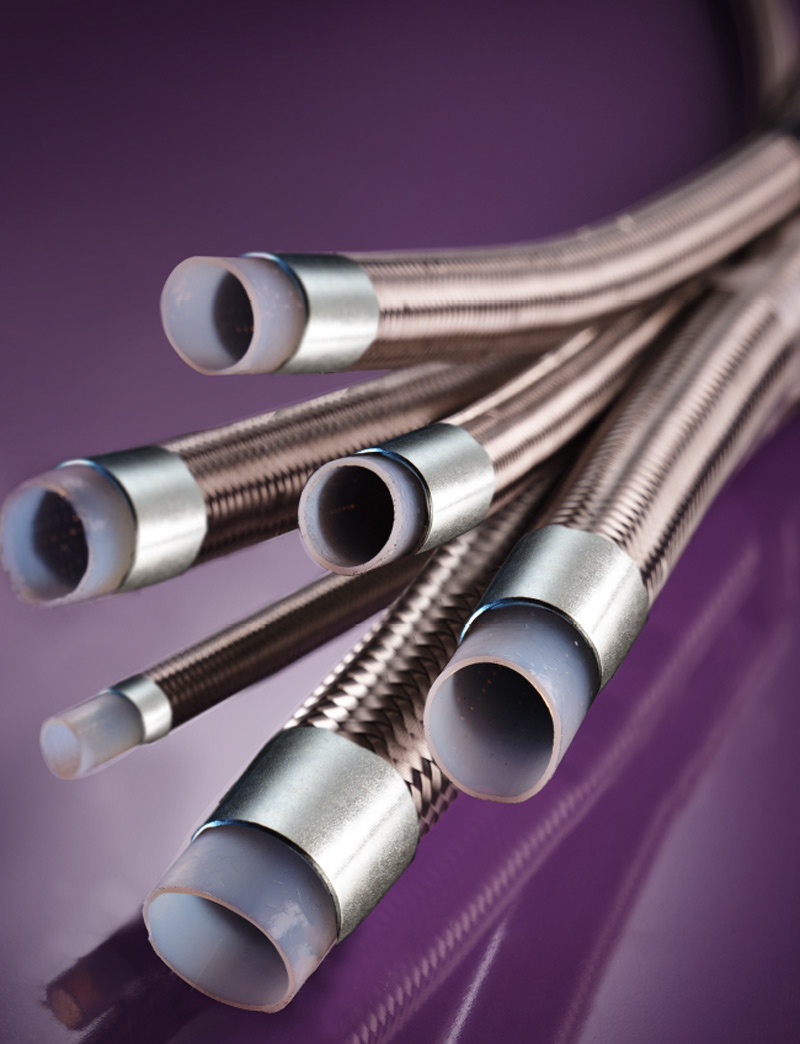

FHL - FHM - FHM DC - PTFE hose

Produced with PTFE resins with high tensile strength and braided with S.S.AISI 304 the Unigasket's PTFE hose are the right solution for the transport of steam, gas, fluids and chemical agents for high temperature and pressions.

The wide range of temperatures reachable (from -70°C to +260°C) by our hoses allow them to be the right solution for many technical problem in any industrial field. We have available special PTFE powders approved by FDA, DVGW and BFR that allow to our hoses to be used with foods and drinks.We have also tested our hoses acc.to EC 2002/72 and DM 174/2004 that have confirmed the possibility to use our hoses in contact with water, food and beverage.

The absence of peroxides that are usually present in the rubber hoses, makes our articles the only one choice in the car and nautical industry, specially due to the new unlead gasoline. Their high resistance to the brake oils makes them the forced choice in the motorcycle and racing field for brake system.

We have realized our flexible PTFE hoses in three types: FHL - FHM - FHMDC to satisfy any requirements and request for technologic performances. The type FHL is the most used for general purpose, the type FHM is mainly for the car, motorcycles field and for intense thermal cycling.

-

Extreme flexibility

High resistance to the aging

Low maintenance

Chemical inertness

-

P.T.F.E. synterized resin smooth bore tube; the particular structure of the PTFE assures high permeability values and a high mechanical stress resistance.

It has dielectricals and fire resistance properties.

-

STD : one stainless steel braid AISI 304

special: one or more braids made by TERILENE®, NOMEX®, FIBER GLASS, AISI 316.

2 braids INOX 304 (only for FHM version)

EXTERNAL COVERAGE : PA-PVC-PU-SILICON

WORKING TEMPERATURES : -70°C +260 °C

FHL